Explosion Proof Lighting Market set to grow according to forecasts – key player Airfal International, AtomSve, Cortem, Glamox, Larson Electronics, LDPI

May 14, 2019 6:00 AM ET

The global explosion proof lighting market valued US$ 250.1 Mn in 2018 and is expected to reach US$ 606.1 Mn by 2027, growing at a CAGR of 10.7% in the forecast period.

The equipment approved for use in a hazardous area is regulated by several certifying agencies. For instance, in North America, usually, UL (Underwriters Laboratories) and FM (Factory Mutual) provide standards, testing and certification in the country although CSA (the Canadian Standard Association) provides the same in Canada. Recently, FM, UL, and CSA have all implemented programs enabling certifications to be valid in both countries. The increasing government regulations for worker safety is the key factor propelling the explosion proof lighting market growth.

Get sample PDF Copy at: https://www.theinsightpartners.com/sample/TIPRE00003155/

Company Profiles

- ABB Ltd.

- Abtech Ltd.

- Adolf Schuch GmbH

- Airfal International

- Alfred Pracht Lichttechnik GmbH (Pracht)

- AtomSvet LLC

- Cortem S.p.A.

- Eaton Corporation Plc.

- Emerson Electric Co.

- General Electric

- Glamox AS

- Hubbell Inc.

Advancement in features of explosion proof lighting is anticipated to provide a prosperous opportunity to the explosion proof lighting market growth

To reduce the combustion risk, the businesses deploy fixtures with approval ratings of Class 1 Division 1 (C1D1) and Class 1 Division 2 (C1D2) inside the facility. Further, fixtures that are designed for oil refineries come with advanced features such as water-tightness and corrosion-resistance. This pertains to frequent exposure to abrasive cleaning solutions. The constant exposure to corrosive agents and water and corrosive agents may cause failure to the lights. This can lead to a serious safety hazard, specifically for workers.

Europe is leading the explosion proof lighting market with a CAGR of 9.5%

The classification and certification for hazardous locations equipment in Europe are described under ATEX (ATmospheres EXplosibles) Directive, which is derived from standardizations established by CENELEC as well as the European Committee for Electrotechnical Standardization. Some of the major industries in the region include ferrous and non-ferrous metal production and processing, petroleum, coal, chemicals, cement, pharmaceuticals, aerospace, passenger and commercial vehicles, rail transportation equipment, industrial equipment, construction equipment, shipbuilding, electronics and telecommunications equipment, electrical power equipment, F&B, paper and textiles. Also, APAC is expected to witness the highest CAGR growth in the explosion proof lighting market during the forecast period.

Light Type Insights

The global explosion proof lighting market by light type is led by LEDs. LED solutions are energy efficient and low maintenance alternative to fluorescent lighting. The rise in demand for better and efficient lighting systems paired with increasing awareness for improving the energy efficiency drives the explosion proof lighting market for the LED systems. Further, one of the major growth drivers for LED systems is the low cost of the systems in comparison with its conventional counterparts. Also, the time required for the installation of these systems is lesser.

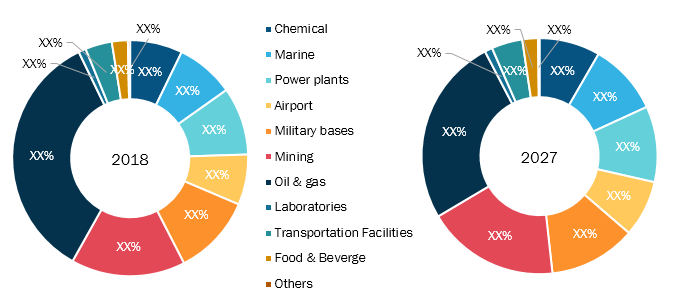

The explosion proof lighting market is segmented based on chemical, marine, power plants, airports, military bases, mining, oil & gas, laboratories, transportation facilities, food & beverage, and others. The chemical industry is foreseen to witness the highest CAGR growth in the explosion proof lighting market during the forecast period. Chemicals have strict requirements, which includes very high illuminance levels and contrast and color rendition. In the place, where chemicals are handled and processed, light fittings need precise vapor protection. Lighting in working atmospheres with chemical substances is a crucial safety issue. The chemical sector deals with flammable, toxic, and explosive substances in almost all single production process. Thus, lightning flashes, as well as over-voltages, are considered as high risks elements for the technical facilities and the staff working near to them.

Buy Now This Report at: https://www.theinsightpartners.com/buy/TIPRE00003155/

About Us:

The Insight Partners is a one stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We are a specialist in Technology, Semiconductors, Healthcare, Manufacturing, Automotive and Defense.

Contact Information:

Contact Us:

Call: +1-646-491-9876

Email: [email protected]

Tags:

Research, Research Newswire, English